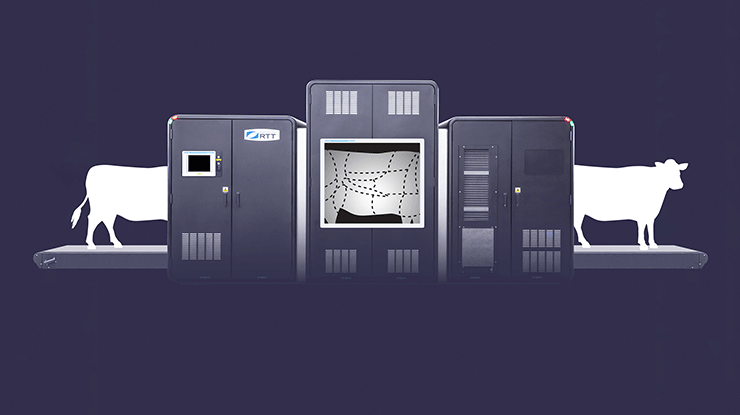

This graphically-modified image shows how work which aims to adapt scanning technology used in the aviation industry to advance objective measurement in the red meat supply chain is now expanding into the possibilities of use with live animals.

Linking carcase measurement and biosecurity

Adaptations to medical and aviation scanning technology to advance objective carcase measurement are now also helping to detect biosecurity risks.

In a project looking at X-ray technologies to identify meat, fruit, vegetable and soil biosecurity risks, MLA is working alongside aviation security screening leaders Rapiscan® Systems to develop a border operations evaluation program with the Australian and New Zealand governments.

According to MLA General Manager for Research, Development, Innovation & MDC, Sean Starling, the project grew from the extensive objective measurement program aimed at building better management systems throughout the value chain.

“We’ve looked to medical CT scanners to evaluate or calibrate how other sensors, such as DEXA (dual-energy X-ray absorptiometry), could benefit our industry,” Sean said.

“Ten years ago, we started engaging with medical CT equipment developers. Their machines weren’t fit-for-purpose for our industry from a continuous online perspective (not a large enough space for a carcase to pass through and product couldn’t go through at fast rate).

“We wanted to evolve this gear to suit our supply chain. So, we looked around the world. The aviation security sector was also doing this work with continuous baggage CT scanning. Some machines were scanning 1,800 bags an hour. Our fastest sheep and beef plants need the equivalent of 1,400 bags an hour.”

Three years ago, MLA reached out to US-based Rapiscan® Systems, whose technology centred on finding explosives in bags.

Rapiscan® showed an interest in expanding into food scanning and agreed to co-invest a program to evolve aviation CT for the livestock industry.

The first of three systems developed is now undertaking evaluation work in Australia, with meat samples being analysed offline.

“We’re hoping it’ll measure lean meat yield, eating quality and animal wellbeing and health,” Sean said.

MLA is now also reviewing two new co-investment submissions from Rapiscan® Systems, looking to move the scanning technology to live animals – one for beef and one for small stock. This would allow the technology to be applied on-farm and in feedlots.

Mal Maginnis, Rapiscan® Systems’ President, said the company is excited to be working so closely with MLA and the Australian and New Zealand governments to help protect the livestock industries.

“This is a great opportunity for us and a new market which we never anticipated when we first designed the system.

“We’re committed to investing in the highest quality technologies and look forward to continuing our work with MLA,” Mal said.