Samantha Rudd administering a cornual nerve block with local anaesthetic to desensitise the horn area before dehorning. Image: Samantha Rudd

Samantha Rudd administering a cornual nerve block with local anaesthetic to desensitise the horn area before dehorning. Image: Samantha Rudd

Sticking power key to dehorning healing

MLA-funded research to develop an effective and commercially viable patch for dehorning wounds is tackling a sticky challenge.

Researchers are exploring the potential of hydrogel wound treatment to overcome the adhesion challenges faced in the development and testing phase of the patch prototype.

The team is focused on further refining the prototype to improve its ability to effectively seal wounds and therefore aid healing and prevent infection.

Researchers from the University of New South Wales (UNSW) have joined forces with The University of Sydney (USYD) team, led by Dr Dominique Van der Saag and PhD candidate Samantha Rudd, to realise this goal and improve the wellbeing of cattle.

Work in this area is vital for both productivity and welfare reasons, as an easy-to-apply wound treatment would not only protect wounds but also potentially deliver pain relief medication, antiseptic and antimicrobial ingredients following dehorning procedures.

Consultation with northern Australian cattle producers has confirmed the need for a cost-effective, affordable patch that is quick and easy to apply. While genetic breeding strategies continue to drive the transition to a fully polled national herd, dehorning remains a necessary husbandry procedure to ensure staff and cattle safety, and retain carcase quality and value.

A sticky situation

Dr Sabrina Lomax, lead scientist at the Livestock Production and Welfare Group at USYD, emphasises the importance of developing a wound patch with effective sticking power.

The nature of dehorning wounds makes this a significant challenge, as blood flow can prevent both adequate adhesion and delivery of any therapeutic ingredients infused into the patch.

“Tri-Solfen’s® pain relief efficacy is limited for dehorning wounds as it performs best when absorbed through mucosal tissue and blood vessels, such as in castration and mulesing wounds.

“Dehorning wounds, however, have very little soft tissue to absorb the product, and the bleeding washes away much of the product, limiting absorption,” Sabrina said.

Earlier experimentation with electrospun polycaprolactone (PCL) patches showed good sticking properties, however the time and cost required to produce them commercially limits their scalability.

Hydrogel potential

The researchers went back to the lab and put their heads together to see how they could come up with an affordable patch that was quick and easy to apply and sealed wounds effectively. Hydrogel is one possible answer.

“We moved away from the PCL patches on their own and sought the expertise of UNSW researchers in the use of hydrogels. Hydrogels can be manipulated to have better adhesion properties as well as the potential to be infused with therapeutic ingredients,” Samantha said.

“We’re working on improving the adhesion of the hydrogel discs – which are like a gel disc rather than a fabric patch. Now we’re looking at how to combine the right combination of hydrogel with the PCL patch.

“We may need to find an engineering solution to develop a type of applicator as getting them to stick in the field raises some challenges.”

The first priority is simply sealing the wound – this alone would help with many of the issues, especially preventing infection.

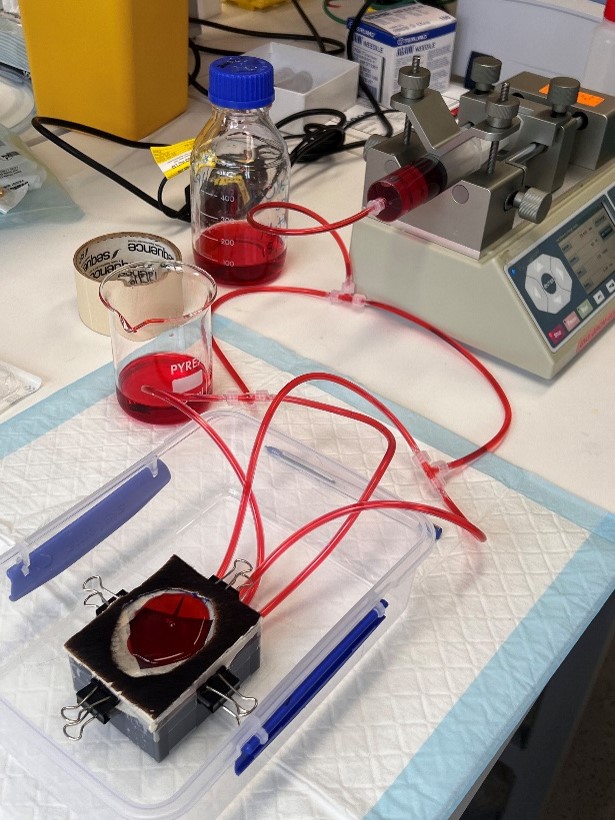

A pump-operated, 3D-printed wound model developed by the team at UNSW. Image: Julian Hovenden

Innovation in the lab

UNSW researcher Professor Penny Martens and USYD technical officer Julian Hovenden have worked extensively on developing and testing various patch solutions.

“The team is testing a model in the lab, where they’re replicating the wound by using a hide, complete with hair, and using high-pressure glycerine to replicate the in vitro dehorning wound model,” Samantha said.

“The glycerine is pumped through the bony surface and the hair, to ensure the patch can stick in real-life conditions.”

This innovative approach to testing is a win for animal welfare as it reduces the need to test the patches on live animals during this early phase of development.

The researchers are hopeful that their ongoing work will soon deliver an effective, easy-to-use patch that will provide positive outcomes for Australia’s cattle industry.

Dehorning dos and don’tsDo:

Don’t

|