Optiweigh lands southern WA – preliminary learnings

25 March 2024

The Project

Stirlings to Coast Farmers (SCF) applied for an MLA-funded project to demonstrate the Optiweigh unit, an in-paddock cattle weighing system, on properties in Southern WA. A large component of the project was to show the economic value of utilising the system in terms of improved labour efficiency, closer monitoring of animal weights and using the weight data to optimise compliance with target market weight specifications in order to receive premium prices.

The SCF-bought Optiweigh trailer landed in Albany in March 2023. As part of the project at least two farmers a year, between 2023 and 2025, will be able to give the system a try on their herd of choice, free-of-charge – well almost! There are some strings attached in the form of surveys to be completed for data collection!

In terms of operation, cattle are enticed onto the Optiweigh with an attractant i.e., a loose lick, lick block or salt. Stepping on, they have their EID recorded and front feet weighed. This information is sent to the cloud and an algorithm applied to calculate total body weight. Farmers can use the data from the Optiweigh to monitor overall herd weight and health to (hopefully) aid in decision making and herd management.

The Bradshaws go first!

The Bradshaw family, who run a mixed farming enterprise in South Stirlings, were the first SCF members to get their hands on the SCF Optiweigh in April this year. Over the period of a few months, they were able to trial the Optiweigh system on three different classes of cattle (steers, heifers, and cows & calves).

Sorting out the set-up

It was quickly apparent that there were a few things that had to be tweaked to generate weight data that was useful to the Bradshaws. Firstly, it seemed that the steers required some time to ‘warm up’ to the Optiweigh, with only a few entering the trailer per day in the first week. The positioning of the Optiweigh in the paddock may have also impacted on herd usage. When the Optiweigh was moved closer to the water point (dam), the daily number of animals entering noticeably increased. The compounding influence of having the Optiweigh in with the herd for only two weeks made this initial set of data difficult to use.

It was also apparent that the type of lick/attractant that was used to lure the cattle into the Optiweigh played an important role at the Bradshaws. In the end it was the sweet loose lick recommended by the Optiweigh manufacturers that seemed to work best.

Lesson learnt

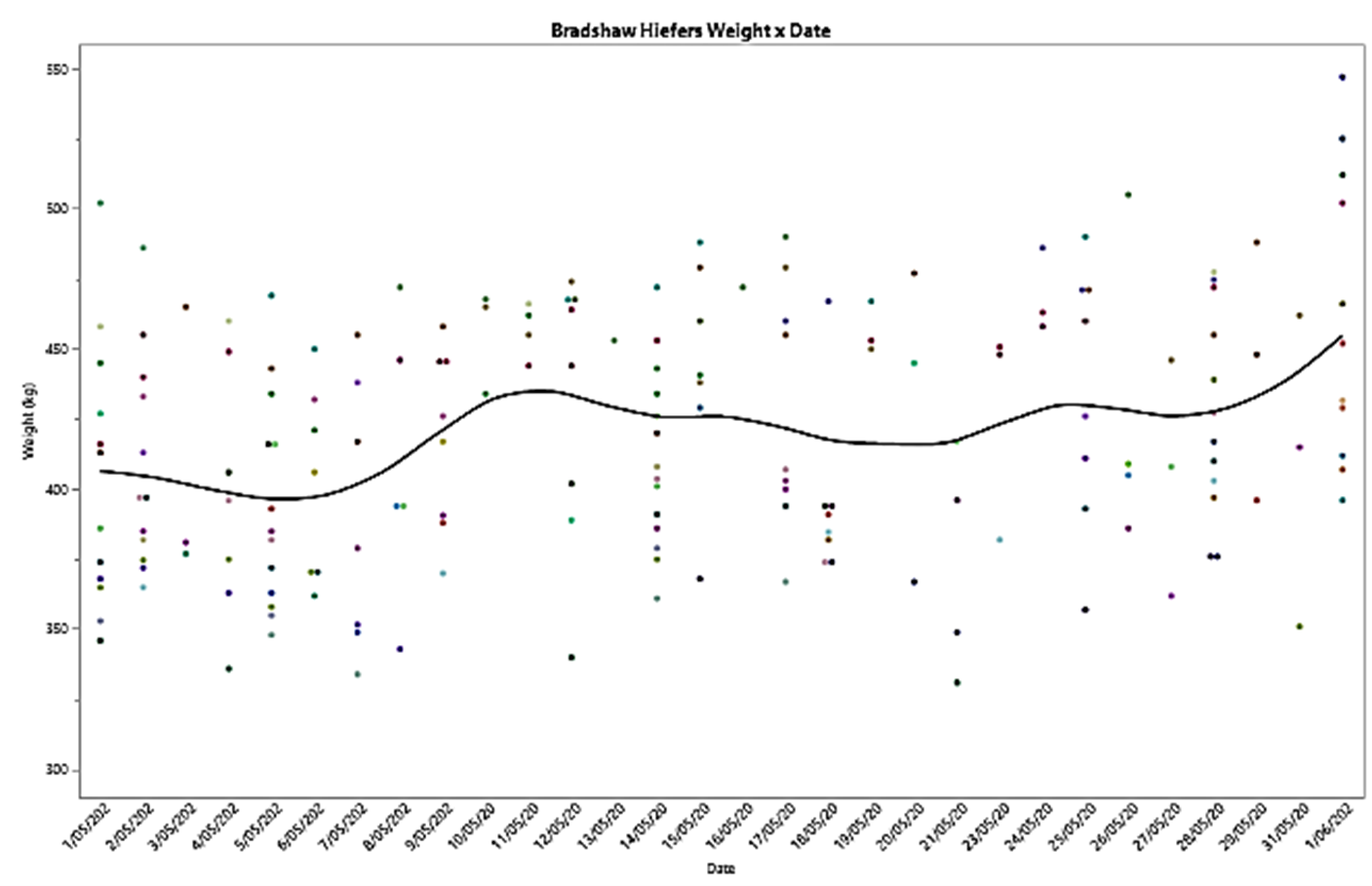

Once some of the finer details had been sorted out (i.e., the location in paddock, the lick, the time left in with cattle), the Optiweigh system started to generate data that was useful. Image 2 shows a graph of the weight data generated when the Optiweigh was placed in the 50ha paddock with a herd of 71 heifers. The individual dots represent the weight data of each animal that entered the Optiweigh, and the line is the average weight of the herd, generated from the individual daily weights.

Image 1: Optiweigh weight data output for the herd of heifers – 1 May until 1 June 2023. The individual dots represent each animal, and the line represents the average weight of the herd.

The data output

There were some issues that came to light after analysing the Bradshaws’ weight data. Most importantly, if you only had outlier cattle (very heavy or very light) using the Optiweigh on any given day, this could skew the average quite significantly – giving cause for, possibly, false concern if the data (individual weights for that day) could not be interrogated more closely. Ideally, the more individual animals using the Optiweigh, the more accurate the average. So, going forward this is the aim of the game.

As a positive however, the Bradshaws were able to use the Optiweigh weight data to make a cattle sale without the need to yard for weighing before the cattle left the farm.

Image 2: Bradshaw family steers give the Optiweigh a go.

The economic analysis

The Bradshaws were asked to complete a survey in order to capture data that could be used to undertake an economic analysis and demonstrate the dollar value of the Optiweigh system. The key findings were:

- The Optiweigh was a positive investment with most of the benefit derived from reduced labour costs (estimated at $5,640/year).

- Assuming the Optiweigh has a life of 15 years, it was determined that it would take 10 years to pay the system off within the Bradshaws’ operation.

Next steps

This MLA-funded project will continue through 2024 and 2025, further trialing the ‘Optiweigh’ in-paddock weighing system with different classes of cattle, and various paddock sizes and attractants across farms in the Southern region of WA. At project completion, local farmers will have information on how to optimise cattle usage on-farm, as well as information that will aid them in making the economic decision of purchasing a system such as this for their own operation.