Subscribe to MSA’s newsletter

For your fill of eating quality information, news and insights.

Factors affecting eating quality

Eating quality is a key purchase driver for red meat consumers. Meeting these eating quality expectations and giving consumers confidence in their beef and sheepmeat purchases is the purpose of Meat Standards Australia (MSA).

MSA is a national beef and sheepmeat eating quality program. It aims to accurately predict eating quality and ideal cooking methods for individual cuts. It is a paddock-to-plate system ensuring that all critical control points that impact eating quality along the supply chain are monitored and managed.

The main factors that affect beef eating quality are:

- Hump height - All breeds of cattle are eligible for MSA grading. Hump height is used as a direct predictor of eating quality in conjunction with hot standard carcase weight (HSCW) and sex. Generally, as hump height increases, eating quality decreases.

- Maturity - Ossification is a measure of the physiological maturity of a carcase, that is, the process of cartilage turning to bone in the vertebrae. As the ossification score increases, eating quality decreases.

- Fat coverage - An even coverage of subcutaneous (external) fat on a carcase ensures an even chilling of all muscles and prevention of dehydration and toughening.

- Marbling - The fat that is deposited between individual muscle fibres and it has a very positive effect on the eating quality of some cuts but is only one of many factors affecting eating quality. This can be attributed to its effect on juiciness and flavour of beef when cooked.

- Hormonal Growth Promotants (HGPS) - They play a vital role in delivering productivity gains, but they can have an adverse effect on eating quality. This effect varies across different muscles.

- Ultimate pH –High pH meat (defined as above pH 5.70) is undesirable and has the following features:

- Dark purple colour. This is known as dark-cutting meat.

- Coarse texture.

- High water holding capacity so less juicy when cooked.

- Reduced shelf life due to bacterial growth in high pH conditions.

- Cooking inconsistencies.

The eating quality performance of an animal is influenced by multiple on-farm factors. Feeding and finishing, together with aspects of animal management such as genetics, animal health and handling, are critical links in the eating quality chain. It is important to be mindful of how feeding and finishing influence eating quality, and implement systems that optimise eating quality potential.

For this reason Meat Standards Australia (MSA) has produced beef and sheep supply guidelines to optimise the eating quality potential of the animal.

Registering as an MSA producer provides you with:

- Access to the carcase feedback/benchmarking functions in myMSA.

- Market access into supply chains that require MSA registration.

- Ability to maximise any potential premiums that may be attached to supply chains.

- Confidence in the end product and the integrity of the supply chain.

- Access to resources, training and the latest information on MSA and eating quality.

Additional factors that affect eating quality

An important element contributing to predictable eating quality performance is the on-farm or feedlot animal management prior to slaughter.

The long period of care and investment in producing an animal with high eating quality potential is most at risk in the two weeks pre-slaughter, and the first few hours post-slaughter. The best carcase can be reduced to a low quality, unacceptable product by inappropriate action in this period. The damage is caused by changes in muscle glycogen (blood sugar) levels.

Glycogen and pH

Glycogen, in essence, is the energy reserve of the muscle. The glycogen level in muscle is increased by feeding (a process taking days) and rapidly reduced by stress (which may only take minutes) or activity in the live animal.

Every animal has a certain amount of energy contained in its muscles in the form of glycogen. At the point of slaughter, the glycogen in muscle is converted to lactic acid that steadily decreases the pH of the muscle, largely determining the ultimate eating quality result.

The more glycogen there is in the muscle, the more lactic acid will be produced and the lower the ultimate pH will be. MSA requires ultimate pH to be 5.70 or less.

If the glycogen in the live muscle falls below the acceptable threshold the resulting meat will have a high pH. Lower glycogen levels can be the result of poor nutrition or other factors such as poor handling and excessive stress.

Meat with an ultimate pH above 5.70 is classified as dark cutting. Characterised by a darker colour, coarse texture, inferior flavour and reduced shelf life, dark cutting meat can be associated with reduced tenderness.

Minimising risk

The most effective way to minimise the risk of high pH is to ensure high levels of muscle glycogen at the point of slaughter. Appropriate feeding and minimising stress in the lead up to slaughter will optimise the amount of stored glycogen.

Feeding and finishing

Ensuring animals are on a rising plane of nutrition, particularly in the 30 days prior to processing, is the best way to optimise glycogen levels and eating quality potential.

Well-planned feeding and finishing systems enable animal condition to be monitored for turn off that meets precise market specifications.

The glycogen bucket

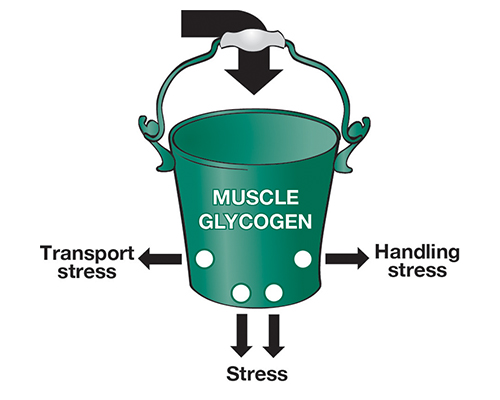

The glycogen relationship can best be illustrated through the ‘glycogen bucket’ below.

Nutrition provided for the animal is the energy pouring into the bucket, which builds muscle glycogen. The holes in the bucket represent the factors that use up muscle glycogen such as exercise or stress. These factors will always be present in some form, but it’s important to minimise their impact. That is, to keep the ‘holes’ in the bucket as small as possible.